Warehouse Management System (WMS)

Warehouse Management System (WMS)

Nowadays, warehouses and distribution centers cannot operate as isolated entities. The ability to integrate storage operations into supply strategies influences a business’s capacity to maximize supply chain effectiveness.

Axional ERP/WMS is a simple and flexible solution that manages the whole supply process, including delivery, storage, classification, transfer and restocking in multiple storage facilities. It also provides the ability to easily alter processes through configurable workflows, all in the interest of higher productivity.

You will be able to provide your customers instant feedback about your company’s ability to provide requested products in the specified amounts. Axional ERP/WMS will allow you to verify the availability of a product and view the status of current and future inventories for finished products, orders in progress, and production schedules.

Inventory management

Axional ERP/WMS includes rich and dynamic configuration capabilities, allowing you to control multiple areas of operations to manage inventory, whether distributed in a network of warehouses or in one centralized environment. Axional ERP/WMS controls all aspects of the warehouse: receiving, tracking, shipping, order management, picking, cross-docking and interleaving.

You can determine the optimum location for each product for receiving, restocking, transferring, and shipping. You will have at your disposal the ability to set flexible rules based on a variety of criteria (product characteristics, quantities received, ABC analysis or stock rotation, warehouse organization and stocking requirements). This will prevent warehouse dispersion and optimize operations.

To accurately reflect inventory status, logistics accounts are used. They are defined by mnemonics which represent the status of stock in the cycle of materials supply and distribution (damaged, retained, available for allocation, ready to be sent, etc.). They allow the stock in each situation to be considered or not considered in the procurement and reserves planning process as well as inventory valuation.

Relevant characteristics of inventory management:

- Sets variables such as units of measurement used to report storage parameters such as minimum logistics and handling, palletizing variables, shrinking measures, size and weight.

- Applies storage systems based on cells or carousels, automatically managing the allocation and arrangement of packages.

- Defines characteristics of each warehouse location: measurements, usage limitations, sharing, etc.

- Controls inventory by product batch as well as expiration dates.

- Manages stock placed in suppliers’ or clients’ premises, also providing the option for them to manage it themselves.

- Controls stocks and inventories in multiple units.

- Manages kits, allowing you to generate picking proposals based on their components.

- Tracking of planned stock based on the receipt of future planned stock, obtained from documents in which the quantities shown are not yet available for internal logistical use or sale. Those documents may be purchase orders, import documents and delivery notes, as well as planned sales.

- Inventory tracking and analysis. Movement tracking by item batch and location, past analysis of current stock, turnover and ABC analysis of stock, average stock level by item, and days of availability according to average consumption, ingoing and outgoing amounts, etc.

- Management and implementation of different stock valuation systems: standard, weighted average price (online or batch), FIFO, LIFO, most recent price of purchase and manufacture. There is also the option to define a customized valuation system, or integrate special characteristics of your logistics processes in valuation.

Planned stock is part of inventory management functionalities. It allows companies to create reserves based on sale orders on purchase orders, purchase delivery notes, and/or imports.

As such, goods shipping processes become much more reliable and service improves, since when goods are received in warehouse logistics they have already been assigned to the end customer in a line item. In this way, no customer needs to wait for stock to arrive at the warehouse for goods to be allocated according to their orders.

At the moment of sale, users can evaluate if goods will be available and, if not, communicate this to the client and add their request to the next wave of purchasing. It also allows companies to calculate the scope of new purchases based on the sales being completed for products which are still not in a wholesaler’s possession, whether because it simply hasn’t arrived yet or because it’s still being manufactured.

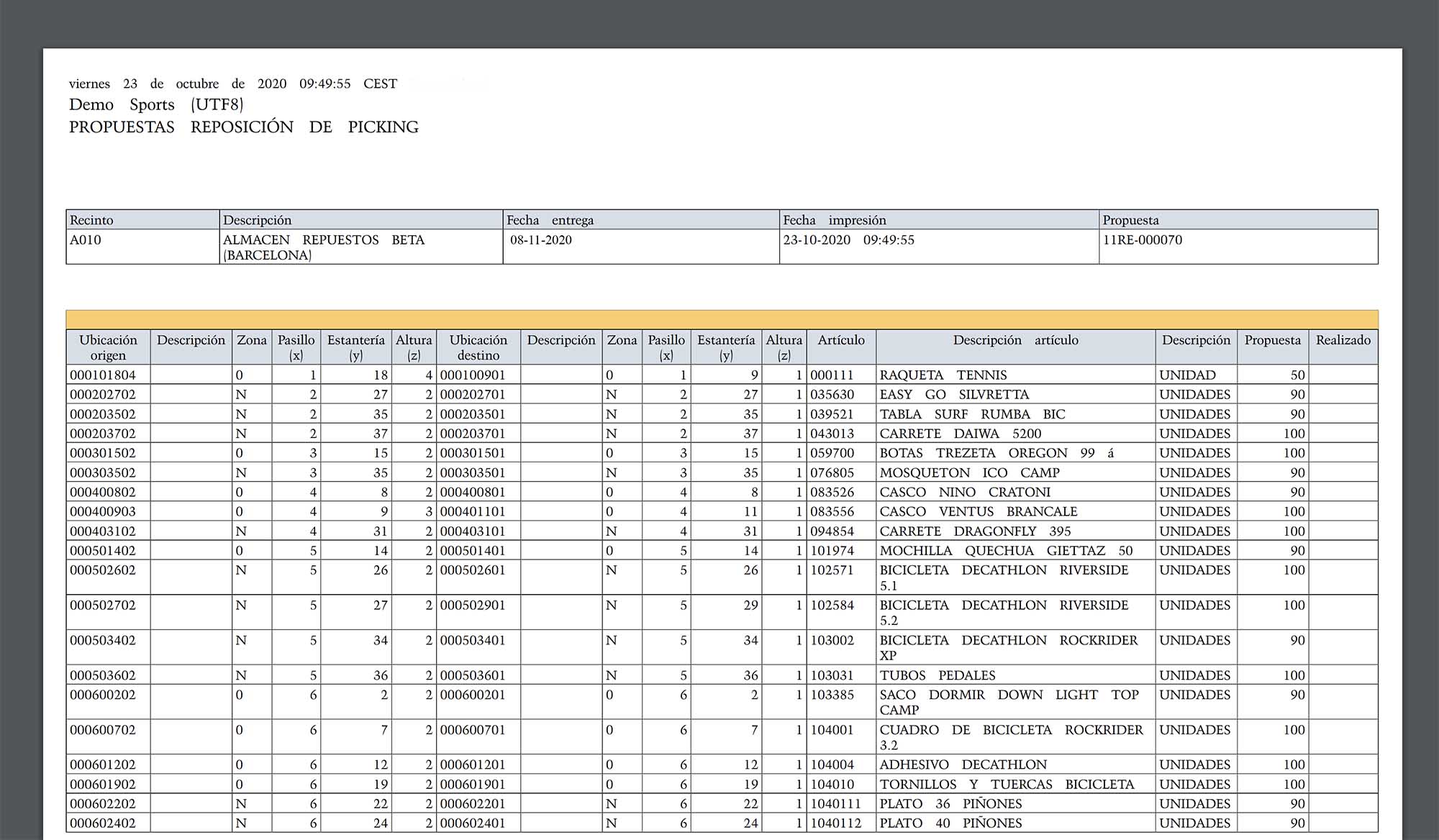

Replenishment picking facilitates restocking functions for picking locations for each item in the warehouse. It ensures availability the moment that order pickers reach the location, minimizing potential wait time for products to become available and optimizing product distribution in the warehouse.

This option can be carried out automatically via picking processes. This would be the case for picking locations with high turnover. It may occur via a general process at the beginning or end of the workday to ensure that all picking locations have a stock level above the set minimum.

Axional ERP/WMS keeps inventory data online, both for finished products as well as their components. It takes into account different stock statuses, e.g. available or pending quality control, or in a processing chain, as well as stock in transit between company warehouses. It also allows companies to assess quantities and amounts of planned stock in advance online.

To enable control of items at the warehouse level, Axional ERP/WMS helps plan and carry out guided or blind counts, either closed or rotating. Inventory counts include all variables needed to establish scope, such as items, item families, stock locations, item turnover, ABC categories, etc. These capabilities allow you to plan and systematize the automatic generation of stock regularizations, maximizing reliability of permanent stock counts.

Stock counts can be performed through a barcode scanner that downloads updated counts to the system.

Receiving

Through the analysis of purchase orders, the system manages forecasted product deliveries, matching the quantities delivered against quantities ordered. Likewise, the system that controls receipt of materials allows you to efficiently manage available stock, delivery plans, as well as picking and shipment systems.

- Matching of items and quantities received vs. purchase orders.

- Document workflow sets controls on deliveries that exceed ordered quantities based on margin percentages.

- Received products can be palletized or grouped before being stocked in the warehouse. A requirement can be set to not stock certain items without palletizing them, according to the product type.

- The receiving system helps manage pallets or multi-product containers, as well as managing different stock units of the same product.

- Automatic creation of batches for inventory control, shipments to customers, and eventual application of picking rules.

Picking, preparation and shipping

In the process of generating picking proposals, the following aspects are considered:

- Item picking rules, managing automatic de-palletizing and the exchange of logistical variables depending on the quantities to be delivered and shipment requirements.

- Settings for multiple units in picking.

- Picking in two phases (wave picking). It follows this sequence: grouping of orders, picking priority by total product quantities from the minimum number of locations, and separation by orders to create individual picking lists for a client. This picking mechanism allows efficient shipping of large volumes of items.

- Picking lists online in simulation mode in order to detect potential deficiencies, which can prevent sending orders if there are shortages of components in the production facilities or loading docks.

- Options for inventory management in FIFO or LIFO mode, and the creation of picking orders in the same sequence in which items were supplied or in reverse sequence, depending on the company’s inventory management model.

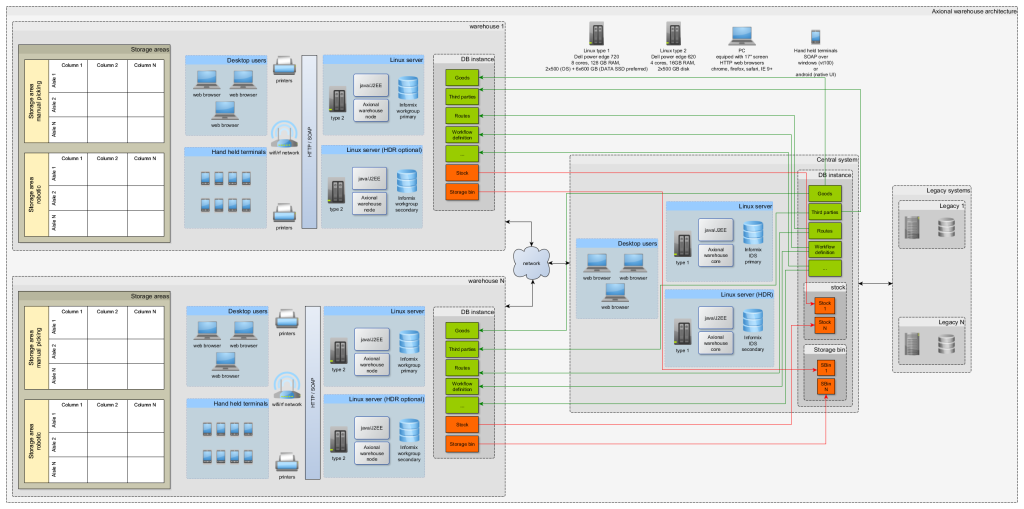

Diagram 'Axional Warehouse architecture'

Axional Mobile WMS

Axional Mobile WMS is a mobile warehouse management system. It provides the ability to control, manage and automate the processes involved in the handling of warehouse items from entrance to shipment. It uses the best communications technology (RF, wireless, 3/4G) to maximize the efficiency of storage operations through proactive management, thus responding to supply requirements and customer needs as quickly and efficiently as possible.

With its radio frequency / mobile capabilities, Axional Mobile WMS allows its operators to use the system in real time, in all the tasks they perform. The use of interleaving maximizes operator productivity, since the tasks they have to perform are attended to directly by the system.

Axional Mobile WMS manages the processing of reception, storage, sorting, shipping, restocking, transport and fleets, storage billing, and EDI integration.

Axional Mobile WMS provides the following features:

- Setup of menus and access to system terminals, screens and specific processes for wireless devices, adapted to the workflows of each warehouse. They can evolve according to varying needs with no programming knowledge required.

- Flexible rules to avoid the breakdown of pallets in the reserve area as much as possible.

- Ability to define restocking tasks, consolidated picking, labeling, stock counts, etc.

- Optimization of task assignment using analysis of the queue of proposed orders, taking into account priority order to ensure availability and minimize additional steps in the picking process.

- Priority analysis of restocking tasks and location of operators when assigning tasks. Both variables are weighted to ensure that operators are distributed optimally, preventing the accumulation of more resources than allowed in the same aisle or zone.

- Reception system for unloading orders, dock control, and outgoing route planning.

- Reading and interpretation of codes including GS1-128 combined information.

Notable benefits

- Real-time information with a wide variety of management and administration capabilities, designed to improve workflow and procedures.

- More accurate information for receiving, stock counting, and picking.

- Mechanisms to ensure the availability of materials while minimizing inventory levels.

- Effective workforce management and operational resource planning, empowering customer service and overall warehouse productivity. Provides support for changing distribution agreements, multi-site operations and increases in shipping and receiving volume.

- Allows the definition of system resources such as equipment, workers, work teams and times of availability, establishing flexible management rules. The result is optimal productivity, resource usage and customer service.

- The use of radio frequency to manage tasks related to locating, picking, restocking and removing items from a warehouse, helping to minimize non-productive time and manage operations proactively.

Empower your business today

Our team is ready to offer you the best services