Maintenance Management (CMMS)

Maintenance Management (CMMS)

The goal of Axional ERP/CMMS is to optimize the use of scarce resources (manpower, equipment, material, and funds) to maintain the facilities and equipment for which a maintenance organization is responsible. The system provides integrated processes which give the manager control over the maintenance of all facilities, as well as maintainable equipment from initial acquisition to disposal.

Axional ERP/CMMS can be used to manage simple or complex facilities, from a single building to a complete campus. It can also be used to manage the maintenance program for a group of equipment, such as a fleet of vehicles. Axional CMMS is designed to serve both internal maintenance departments and maintenance services providers.

The system is integrated with our mobile solution Axional Mobile CMMS to support employees in the field.

Axional ERP/CMMS includes the following modules:

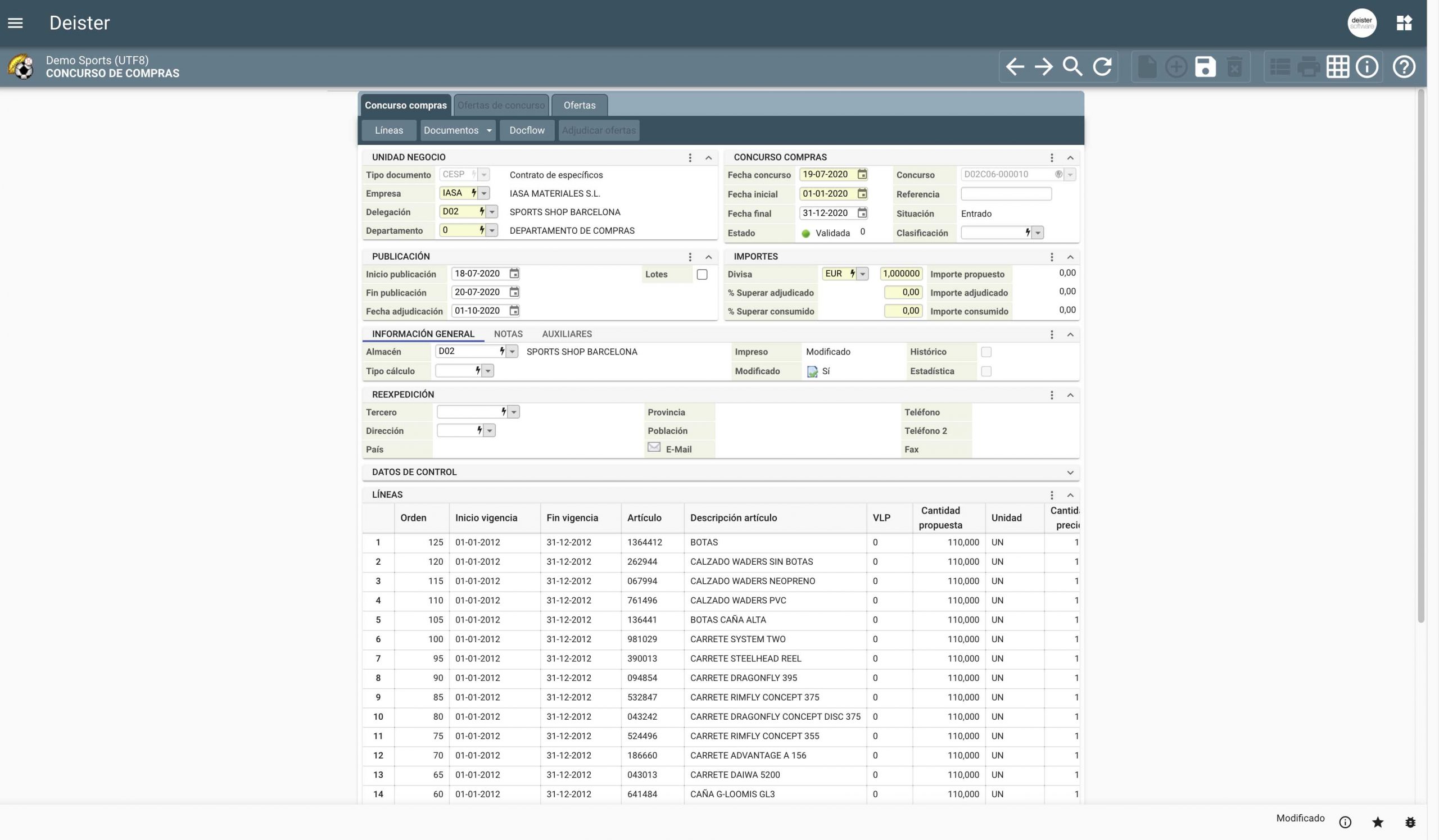

Asset management module

The Asset Management Module tracks all types of equipment, components, systems and locations. It manages the entire lifecycle of assets, from acquisition and installation through repair cycles and eventual replacement. Every activity performed with a specific asset is logged in an “equipment book” or work history which records the history of that asset. Managers can track work histories, operational event logs, current condition status, and costs for all company assets.

Assets can be organized hierarchically in several levels, from complex production lines to assemblies to small components. The system facilitates the management of repairable spares, components and sub-assemblies through their entire lifecycle.

Using this module, operators can define and track locations in which equipment operates. The locations can be organized into logical groups or hierarchies. The Maintenance Scheduling Module can issue Work Orders either against the location itself or against specific equipment in the operating location.

Resources management module

The system can manage all types of personnel: the company’s own employees, personnel from third party maintenance companies, or external individual specialists. The objective is to help managers ensure manpower availability.

The module provides a full record of employee information, including training, hourly wages, individual safety issues, etc. Thanks to the integration with corporate applications, the module also knows the employees’ schedules and holiday entitlements. It uses all this information about availability and capability to assign personnel to work orders.

The Resources Management Module provides the information which maintenance managers need to ensure their tools are available and in good working condition when they need them. Tools can be reserved by scheduled tasks and through Work Order requests. Managers can track specialized tools required for specific tasks or work orders.

The module maintains the calibration histories for measurement equipment, as well as the history of equipment assignment.

Contractor manager module

External labor costs are becoming increasingly important in all operations and maintenance environments. The Contractor Manager Module tracks external labor (contractors, maintenance services and outsourced labor).

For vehicle fleet maintenance, the system includes various useful capabilities:

- Drivers can notify the system of breakdowns or any trouble using mobile devices.

- When the failure is recorded, the system will make a proposal based on contractor information:

- Call the contractor maintenance service company closest to the vehicle.

- Call the contractor maintenance service company with the profile best suited to the failure type.

- Assign the internal employee with the most appropriate profile and lowest workload.

- Automatic notification to drivers for scheduled maintenance review.

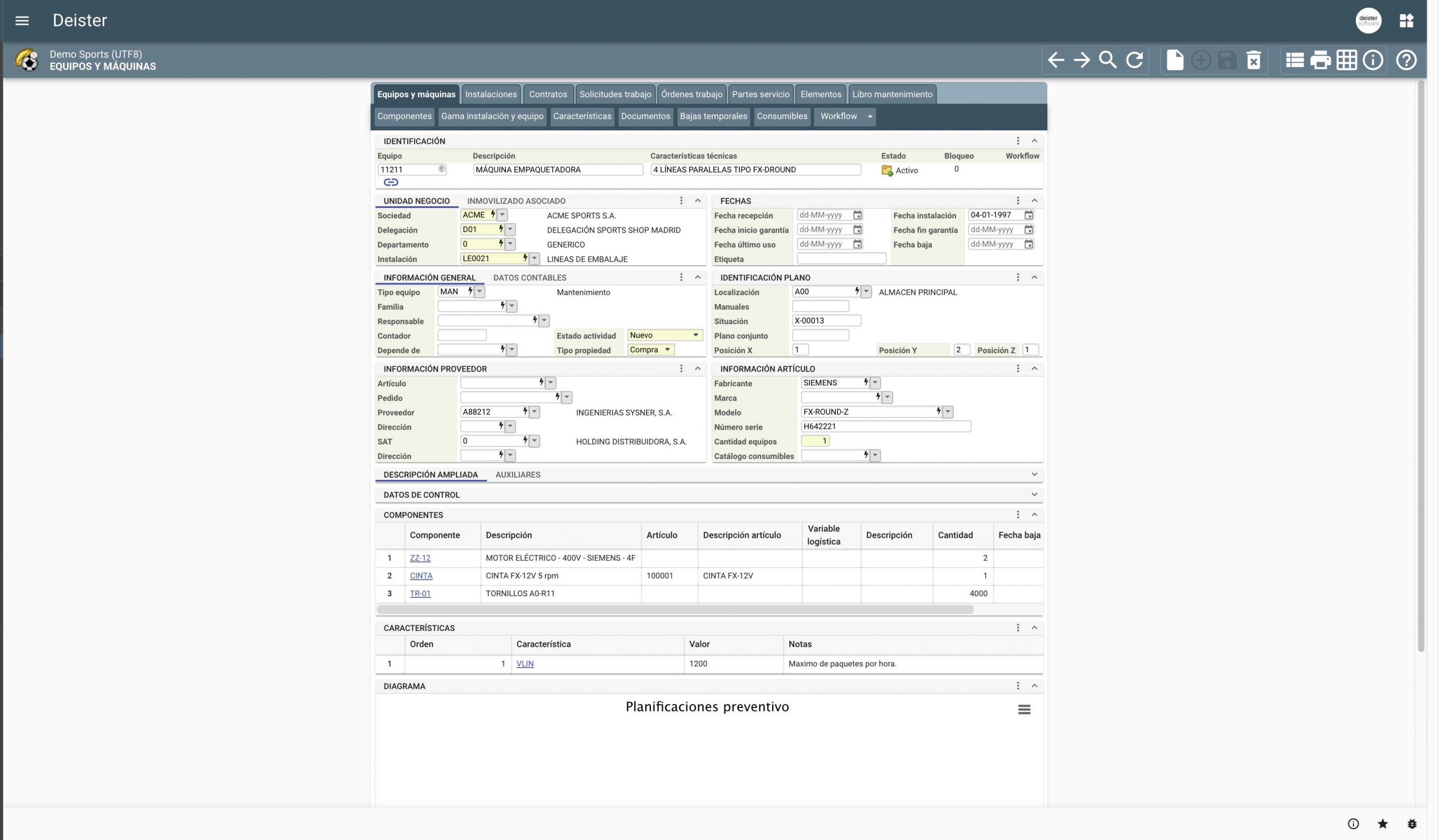

Maintenance scheduling

Axional ERP/CMMS is a powerful and dynamic scheduling system that can create and administer work orders based on preventative, inspection and condition-based maintenance information.

Work Orders are created and scheduled automatically based on information from preventative maintenance programs. There are numerous scheduling options available to generate work orders:

- Schedule by calendar, both fixed and elapsed dates (Preventive Maintenance Guides).

- Schedule by equipment metrics, such as: operating hours, production counts, mileage, etc.

- Schedule by equipment condition or alarms.

- Schedules based on Operations/Production planning.

- Opportunistic scheduling (based on machinery availability, or doing preventative tasks during machine downtime).

Preventative Maintenance Guides (PMG):

- Individual equipment can be assigned to several Preventive Maintenance Guides.

- Each PMG can be scheduled independently.

- Axional CMMS allows for the maximum level of complexity to define a PMG. Users can include:

- Descriptive texts for procedures.

- Checklists.

- Physical parameters to be controlled, including the acceptable value range (temperature, pressure…).

- Attachment of documents, pictures or videos to the PMG.

- Technician profiles required for each task.

This broad set of information helps managers ensure that procedures are followed properly by operators during equipment checking or fixing, even for new hires.

The ability to manage work requests, labor assignments, planning, and scheduling allow companies to make the most of their resources while improving productivity. Axional ERP/CMMS uses Work Orders to track all aspects related to work performed on assets: from installing new equipment to carrying out preventative maintenance tasks or managing critical shutdowns.

After creating a new Work Order, the scheduler module breaks it down into individual tasks and assigns them to the appropriate employee, matching task types with technician profiles and abilities and checking personnel availability. If external labor is required, the Scheduler uses the Contractor Module to assign the external company best suited for the Work Order. Tasks can be grouped together in a “task route” and scheduled as a single item. Work orders are also grouped logically by the system and scheduled together to reduce asset downtime.

Planners can define and sequence work for multiple assets based on location and/or equipment. The system shows calendars with start/end date illustrating shifts, holidays, and vacations. Calendars can be viewed by month or day, displaying total work hours available.

The associated tools are reserved for Work Orders tasks. The assignments proposed by the system can be reviewed and modified by managers, using a workflow module.

Newly generated Work Orders can be printed, including all technical documentation attached to the Preventive Maintenance Guides or linked to assets. For external maintenance services, new Work Orders can be notified via SMS, e-mail, B2B (WebService, Portal) or fax. When using the FIS-CMMS module, all this information is available through mobile devices for employees in the field.

The system allows designated plant personnel to submit work requests to the maintenance planner. They also can track the progress of their work request from request approval through to completion. Work requests can be entered directly, or accessed via a browser, mobile device or via email.

Upon acceptance of the work request, the Contractor Management Module will propose the best suited maintenance service or the available internal technician. Work requests are used by planners to develop daily plans and manage backlogs to lower response time and equipment downtime.

Track work progress

Axional ERP/CMMS enhances the company’s capability to track and manage work requests, labor, planning, and scheduling. All aspects related to work performed on assets are recorded through Work Orders:

- Tracks job time, response time, machine downtime and other user-defined metrics.

- The module records and tracks multiple labor, parts and material costs.

- Technicians and operators can easily capture labor, parts and material costs by customer, building, department, cost center or other user-definable criteria.

- The system allows for user-definable causes, failure and remedy codes specific to asset types.

The system allows planners to view detailed planning information: work plan, scheduled costs, labor, materials, equipment, failure analysis and related documents. They can monitor outstanding Work Orders by searching the Work Order backlog using any field. They can manage work order assignments by, for example, viewing all work orders, or viewing work orders assigned to or by a particular person.

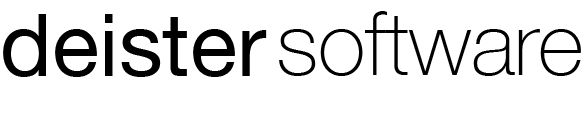

Purchasing and inventory management

Axional ERP/CMMS helps companies maintain an optimal inventory of parts and supplies. It includes a Purchasing module to initiate the requisition of material against a work order and track the delivery and cost data of the item when the material arrives. Its database handles all the information related to items, including non-structured data such as drawings, schemas, etc.

Purchase requisitions or purchase orders can be created both for materials and for services. Purchase requisitions are automatically converted to purchase orders. When necessary, operators can create special orders by entering item descriptions as line items for parts not in inventory database.

The system includes several useful features:

- Control of expiration dates of supplies.

- Extensive set of functions for inventory valuation.

- Use of rotating inventory method

- Very flexible receiving method, back order or cancel any amount on order, split quantities for individual line items, apply individual discounts to items, etc.

- Tracks item costs by last cost, average cost or user-defined standard cost.

- Bar code management of parts.

The purchasing cycle is fully integrated with other enterprise financial applications, either from Axional or from third parties, allowing for two-way (PO/Invoice) and three-way (PO/Receipt/Invoice) matches. Parts inventory records are updated automatically and Work Order costs are automatically transferred to financial applications and associated with the corresponding Cost/Profit Center.

Reports and graphs

The system can provide many types of reports for use in managing the organization’s resources, preparing facilities, using key performance indicators (KPIs) or metrics in evaluating the effectiveness of current operations, and making organizational and personnel decisions. In today’s maintenance world, Axional CMMS is an essential tool for the modern facilities maintenance organization.

Reports can be previewed on-screen and on mobile devices, printed or exported (Excel, PDF…). Some of the pre-built reports are:

- Compare real-time budgets or estimates against current and past work orders.

- Individual reports for each employee, including attendance, vacation, sick and non-productive work time.

- Inspection data to support Predictive Maintenance.

The history module contains the maintenance histories of the facilities and equipment. It includes summaries of PM, repairs, rehabilitation, modifications, additions, construction, and other work affecting the configuration or condition of the items. All completed and canceled work orders are recorded as well. The maintenance history records can be used to support proactive maintenance techniques such as root-cause failure analysis and reliability engineering.

Empower your business today

Our team is ready to offer you the best services